MicroGuard™

Anti-Microbial Coating

DESCRIPTION

MicroGuard™ is an industrial grade UV cured hard coating that provides superior hygiene surface performance to materials including plastics, wood and metals.

Since its introduction back in 2016, MicroGuard™ has been applied and used extensively throughout many industries such as healthcare, food processing, retail and education where cleaning is of paramount importance. This unique coating can be applied to plastic sheet materials, moulded components, door furniture, thin plastic films to name a few.

Based on a Urethane Acrylate Monomer, the coating provides excellent abrasion and chemical resistance together with a good level of UV stability.

BENEFITS

• Bacterial protection – 99.99% effective against common bacteria including E-coli, MRSA & Salmonella.

• Viral Protection – provides a level of protection against viruses such as FCov and Phi6 bacteriophage.

• Abrasion Resistance – Scuffs, chips and scratches are vastly reduced in both quantity and severity.

• Chemical Resistance – Protection against common cleaning chemicals without worry of damage.

• Optical – Optically clear finish available, making it ideal for medical visors and hygiene screens.

• Matt Finish – Matt or Satin finish available for Anti-Glare application or if a textured finish is required.

• Durability – All Peerless coatings enhance the life of any plastic substrate.

• Tested – Independently tested against Bacteria & Viruses.

TECHNICAL DATA

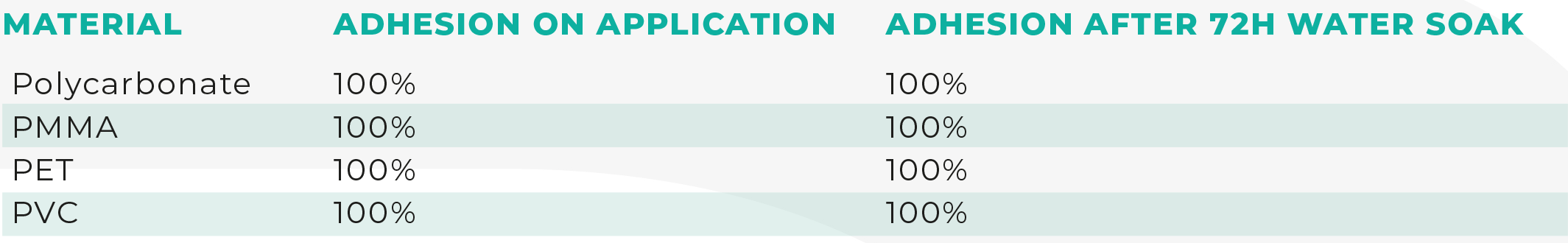

COATING ADHESION using test method ASTM D3359 DN53 15

COATING HARDNESS using test method ASTM D3363 and ASTM D1003.

As the tests employed for coating hardness are substrate dependant, these tests have been carried out on both PMMA and Polycarbonate.

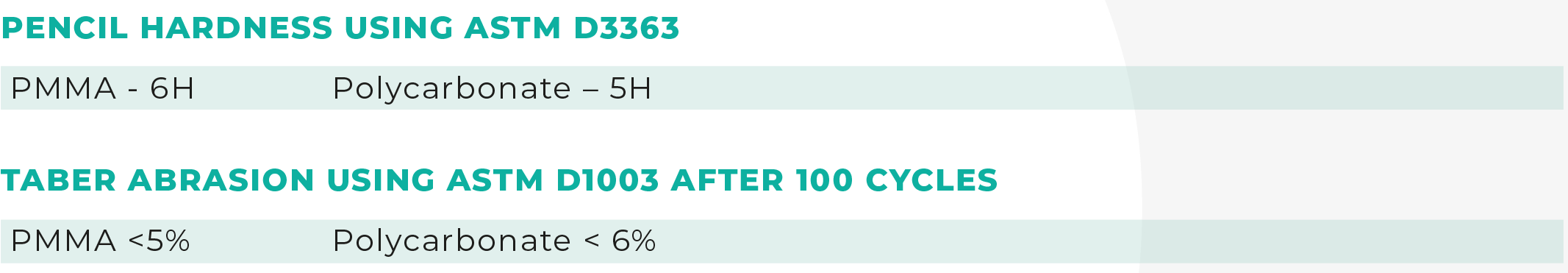

CHEMICAL RESISTANCE using ISO2812 test method.

This test was completed at 15 minute intervals for 8 hours and then left for a total of 24 hours.

LIGHT TRANSMITTANCE - CLEAR ONLY

This is dependent on the substrate to which it is applied but the coating itself typically reduces the light transmission by less than 1%.

O2 AND WATER VAPOUR TRANSFER to ASTM D6701 in triplicate.

Average water vapour transfer of a coated piece of Polycarbonate was reduced by 0.5g/m2 or 28%, against an uncoated piece of the same substrate. Actual WVTR at time of testing for coating only 1.6g/m - day.

FIRE TESTED to CS.25.853 (A) app.f part 1 (a) (i)(v)

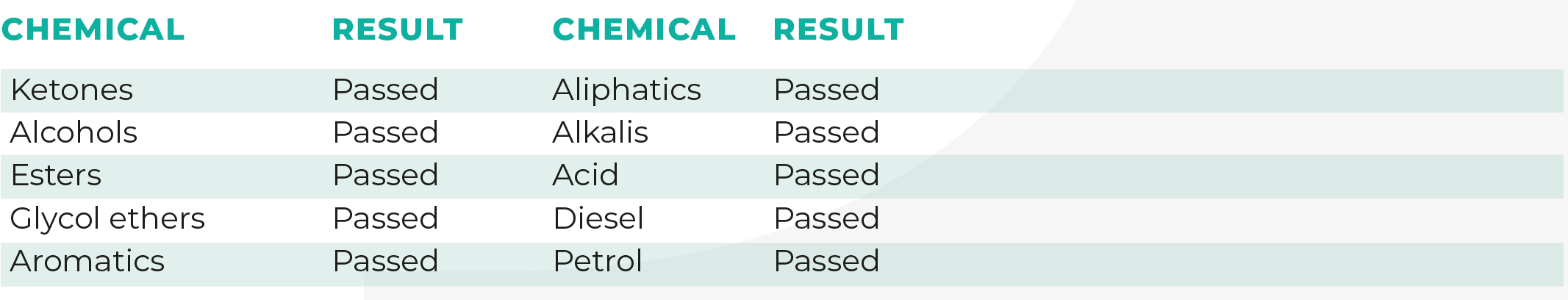

ANTI-MICROBIAL PERFORMANCE using ISO22196 test method.

Under test method IS021702:2019, MicroGuard™ has proven to reduce the presence of FCoV Feline Coronavirus and Phi6 bacteriophage after 2 hours.

The information provided herein was believed to be accurate at the time of preparation or prepared from sources believed to be reliable, but it is the responsibility of the user to investigate and understand other pertinent sources of information, to comply with all laws and procedures applicable to the use of the product and to determine the suitability of the product for its intended use.

All products supplied by Peerless Plastics and Coatings Limited are subject to the Peerless Plastics and Coatings Limited terms and conditions of sale.

Peerless Plastics & Coatings Limited

16 - 20 Howlett Way, Thetford IP24 1HZ

01842 75033 • sales@peerless-coatings.co.uk • peerless-coatings.co.uk

Company Registration No. 7079469 - VAT Reg. 981153418